How to install/replace a rear motor coreUpdated a month ago

Motor Core Installation Instructions

Time: Total install time 30 mins

Bikes covered: X-class, Kepler, and Grizzly models with Bafang motors

Tools needed:

White Lithium grease

Torque wrench that can provide 2nm-50nm

21mm socket

3mm and 4mm Allen wrench

Flush cutting pliers

Step 1: Power cycle the bike by removing the battery and holding down the power button to remove all current from the electronic system.

Step 2: Shift your bike into gear 7 with the button on the front of your shifter on the right side of your handlebar. When shifting, cycle the pedals to ensure the derailleur moves the chain to the 7th gear.

Step 3: Install your Handlebar Jacks on both grips of your handlebars and find something to protect your seat and the rear of your frame with.

Be very careful when you flip your bike over. Ask a friend to help you because it can be awkward to do by yourself.

Step 4: Cut the zip ties off of the motor cable.

Step 5: Unscrew the metal ring on the motor cable and disconnect it.

Step 6: Use a 21mm Socket driver to remove both axle nuts completely.

Step 7: Use a 4mm Allen wrench to remove the bolt from the Torque Guard and torque arm.

Step 8: Raise the derailleur and drop the chain from the chain ring. Let the chain hang on the pedal.

Step 9: If the torque arm is stuck, use a screwdriver to carefully pry it from the frame being sure not to scratch the paint.

Step 10: Lift the wheel straight up out of the dropout.

Step 11: Use a T25 Torx tip wrench or (4mm Allen, 3mm Allen) depending on the hardware needed.

Step 12: Next, remove the motor shell cover bolts with the necessary wrench (depending on the hardware).

Step 13: With bolts pulled out of the cover, lightly/gently tap the axle on the opposite side of the wheel to pull the core out.

Once it starts to move, it should look as below

Step 14: Pull the motor core being sure to keep every part on the axle (thrust washer, planetary gear, axle key, etc).

Step 15: Using white lithium grease, fully lubricate the planetary gear.

Step 16: Check that your axle key is not damaged in any way. Insert it fully into the slot above the center gear.

Step 17: Fully lubricate the center gear.

Step 18: Slide planetary gears into place on the axle making sure the axle key is in place. Clean up any excess grease on the stator or clutch.

Step 19: Place the thrust washer on the axle.

Step 20: Keep the wheel vertical when replacing the core to ensure the thrust washer and planetary gear/axle key stay in place.

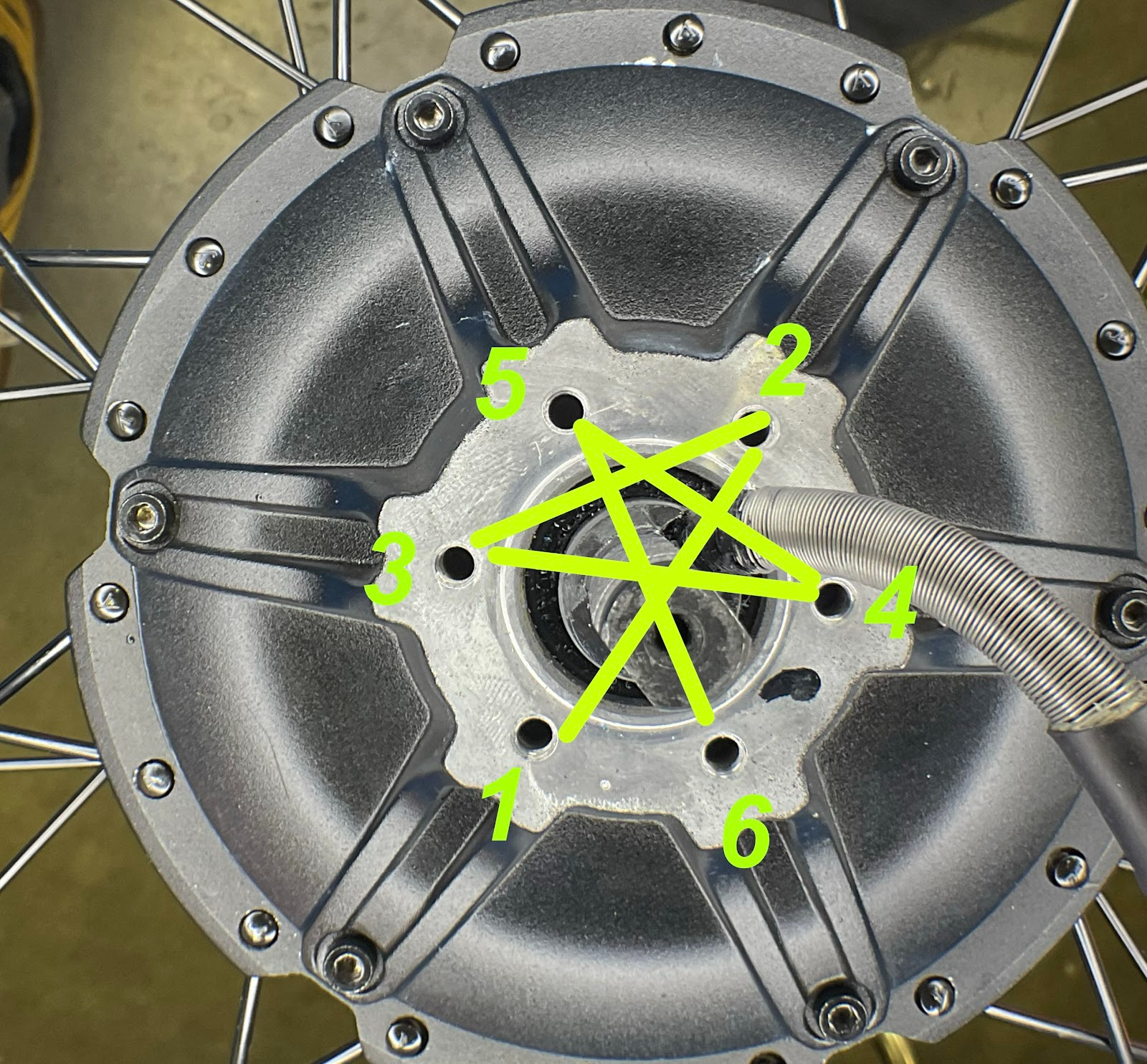

Step 21: Replace cover bolts in a star pattern as shown below. Torque to 2-3nm.

Step 22: Replace rotor bolts in a star pattern as shown below. Torque to 5-6 nm. Ensure that the writing on the brake rotor is visible and facing away from the motor.

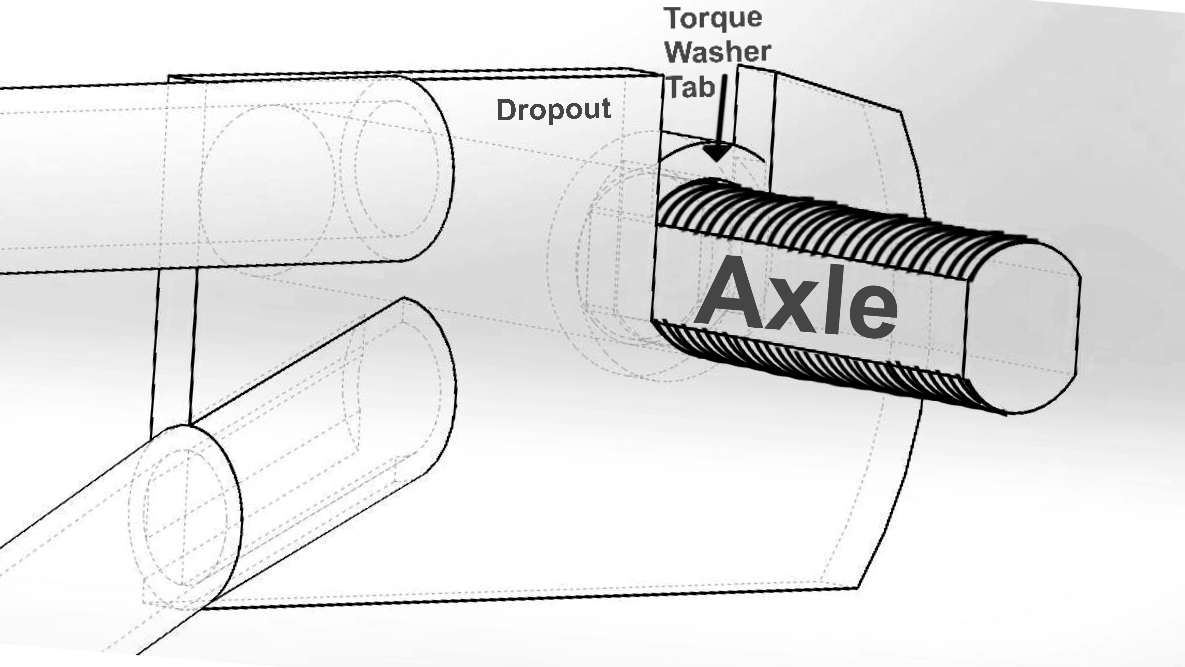

Step 23: Put torque washers on both sides of the axle with the tab facing away from the hub body.

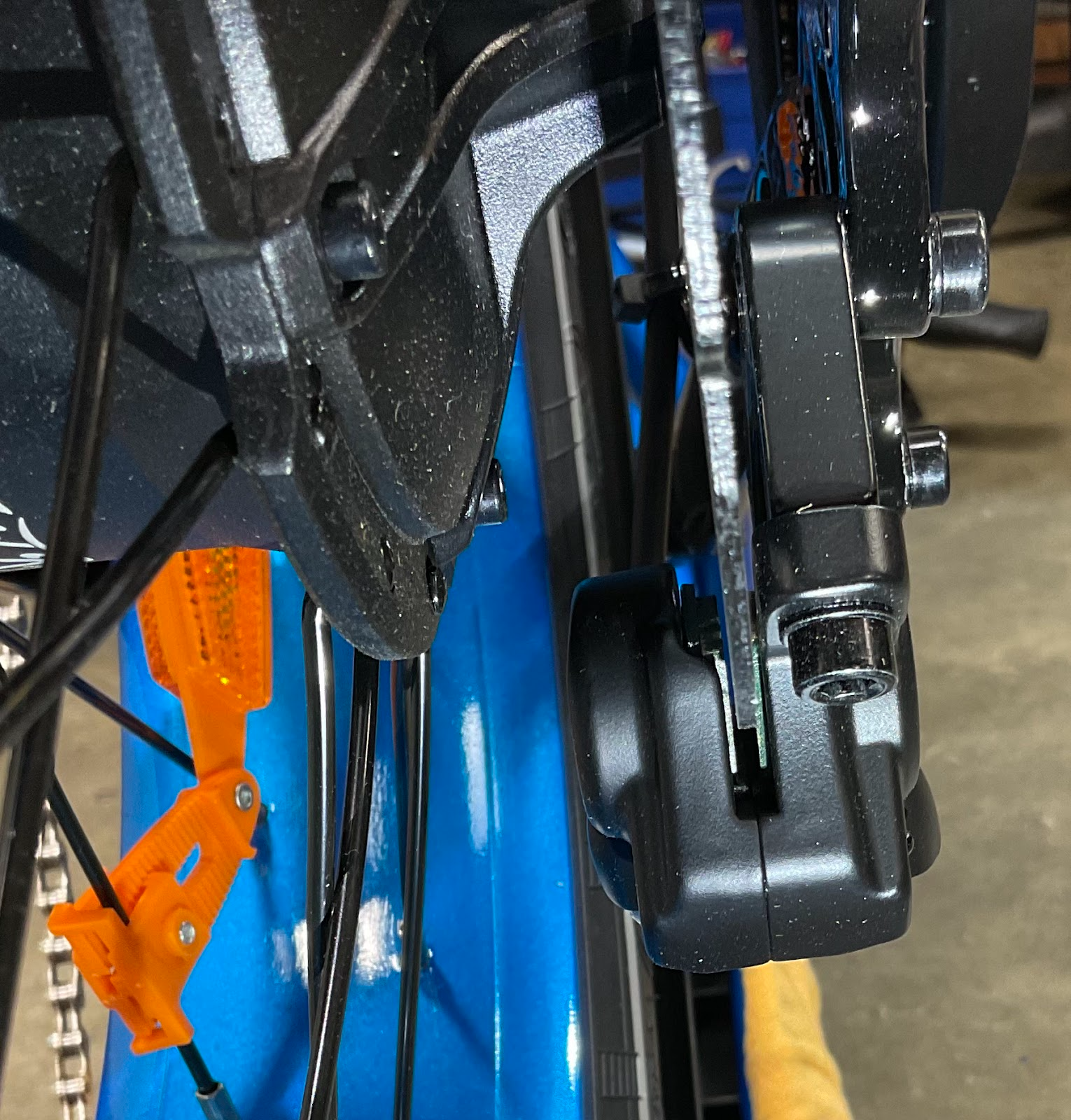

Step 24: Check that brake pads are spread apart well enough to easily slide the brake rotor into them.

DO NOT PULL BRAKE LEVERS DURING THIS PROCESS, IT WILL BE DIFFICULT TO SPREAD THEM IF YOU DO.

Step 25: Check that your hardware is set up so that both torque washers will be inside the frame with the anti-rotation tabs facing out.

Step 26: Ensure the axle is in line with the placement of the dropout, and the brake rotor falls between the brake pads.

Step 27: Align the chain with the 7th gear (smallest sprocket).

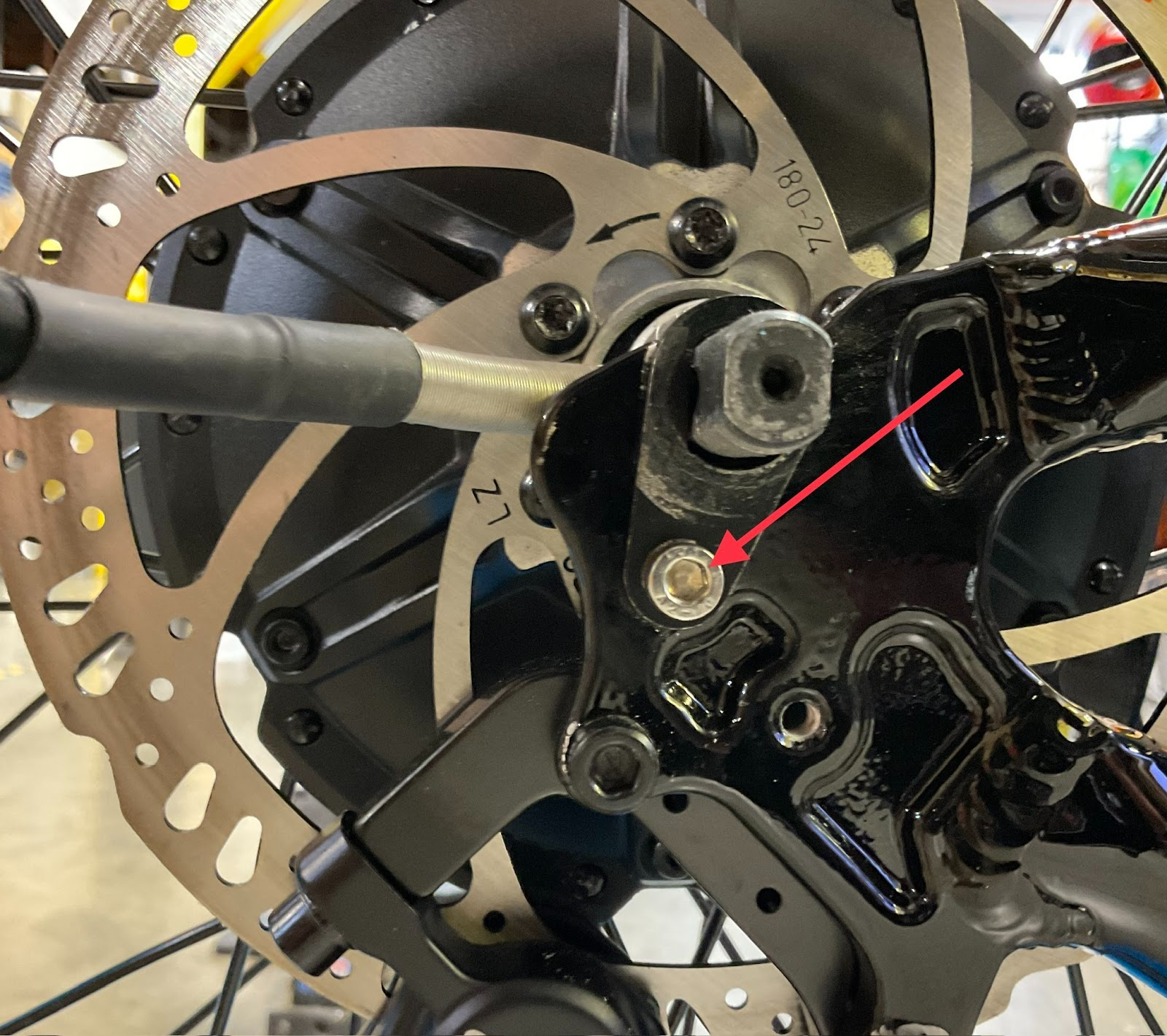

Step 28: With the wheel in place, install the torque arm with an M5 bolt using a 4 mm Allen wrench.

Step 29: Install torque arm derailleur guard with M5 bolt using a 4mm Allen wrench.

Step 30: Install axle nuts and torque to 40 nm.

Step 31: Replace zip ties after connecting the motor cable, being sure that brake the rotor bolts are clear of the motor cable and the brake line is not touching the wheel anywhere along the brake hose.

Step 32: Make sure your tires are fully inflated and your chain is in place before a test ride.